To ensure patient safety and equipment reliability, we recommend repairing or replacing worn components before failure, which is why we emphasize a proactive preventative maintenance program. However, despite careful maintenance, equipment failures may still occur.

Our engineers and technicians hold advanced degrees in Biomedical & Electrical Engineering and have decades of combined industry experience working with biomedical devices. We are trained and certified by leading manufacturers to perform advanced service and repair work. Our team addresses repair issues quickly and efficiently, ensuring your equipment remains safe, reliable, accurate and patient-ready. We can also restore neglected or poorly maintained devices.

A sample of some of the equipment we service includes Ventilators, Oxygen Concentrators, BiPAP, CPAP, Lifts, Scales, Vital Monitors, Blood Pressure Machines, Pumps, Compressors, Air Mattresses, and many more.

Our repair services begin with a full diagnostic check, followed by detailed repairs and conclude with verification testing. We are committed to providing the highest quality service and maintaining strong customer relationships.

Diagnostics

When equipment is defective, we perform a functional performance assessment followed by a comprehensive diagnosis to identify the problem and its root cause. Once identified, we determine the best course of action, whether it involves system adjustment, component repair, or replacement. Customers are informed and approve all repairs before proceeding. If the repair is too extensive, we recommend replacement.

Electrical Repairs

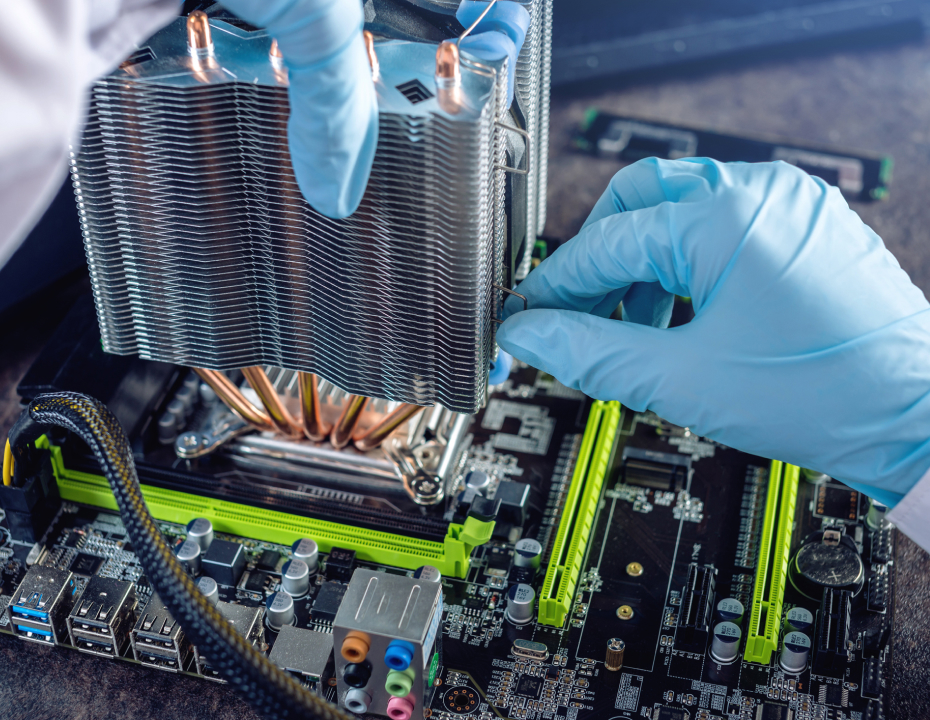

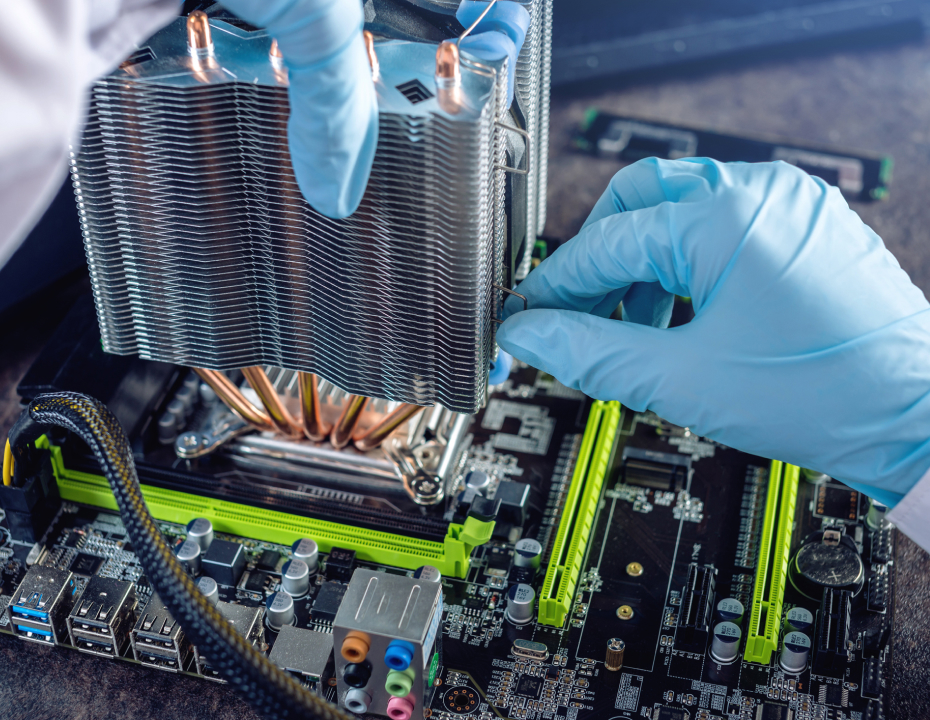

Our team is factory-trained and certified by leading manufacturers to repair medical devices and electronics. Our in-house electronics lab is equipped with state-of-the-art tools to handle a variety of electrical issues, including AC/DC power supplies, batteries, switches, relays, printed circuit boards (PCBs), wiring, connectors, power cords and many more. After repairs, we perform electrical safety testing to ensure continued compliance with safety standards.

Mechanical Repairs

Common wear and tear caused by continuous mechanical stresses can lead to breakdowns, even with regular maintenance. Our skilled technicians are trained to repair a wide range of mechanical systems and failure mechanisms that can manifest either externally or internal within the device.

We maintain a strong adherence to quality workmanship, using only quality components, and delivering reliable results.

System Repairs

With the increasing complexity of modern biomedical equipment, system-level repairs often involve software and firmware updates, as well as resolving compatibility and communication issues with peripheral devices. Our team is equipped to handle these challenges efficiently.

Verification Testing

The final step in any repair is verification testing to ensure the device meets manufacturer specifications and complies with safety standards. After testing, we provide a detailed report outlining the problem, corrective steps implemented, and any components replaced.

Diagnostics

When equipment is defective, we perform a functional performance assessment followed by a comprehensive diagnosis to identify the problem and its root cause. Once identified, we determine the best course of action, whether it involves system adjustment, component repair, or replacement. Customers are informed and approve all repairs before proceeding. If the repair is too extensive, we recommend replacement.

Electrical Repairs

Our team is factory-trained and certified by leading manufacturers to repair medical devices and electronics. Our in-house electronics lab is equipped with state-of-the-art tools to handle a variety of electrical issues, including AC/DC power supplies, batteries, switches, relays, printed circuit boards (PCBs), wiring, connectors, power cords and many more. After repairs, we perform electrical safety testing to ensure continued compliance with safety standards.

Mechanical Repairs

Common wear and tear caused by continuous mechanical stresses can lead to breakdowns, even with regular maintenance. Our skilled technicians are trained to repair a wide range of mechanical systems and failure mechanisms that can manifest either externally or internal within the device.

We maintain a strong adherence to quality workmanship, using only quality components, and delivering reliable results.

System Repairs

With the increasing complexity of modern biomedical equipment, system-level repairs often involve software and firmware updates, as well as resolving compatibility and communication issues with peripheral devices. Our team is equipped to handle these challenges efficiently.

Verification Testing

The final step in any repair is verification testing to ensure the device meets manufacturer specifications and complies with safety standards. After testing, we provide a detailed report outlining the problem, corrective steps implemented, and any components replaced.